Products

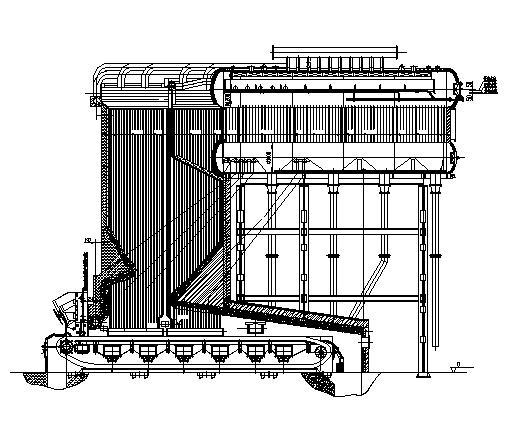

SZL front-mounted biomass boiler assembly

Category:

Biomass boiler

Tel:

E-mail:

Descriptions

The SZL furnace front biomass boiler is developed by the company using new technologies. The boiler has many advantages such as sufficient output, high thermal efficiency, stable and reliable operation, strong overload capacity, wide fuel applicability, and energy saving and environmental protection.

1. The furnace front structure completely overcomes the phenomenon of overheating and bulging caused by the boiler drum being directly exposed to the furnace, and the arrangement of the heating surface is more reasonable.

2. The membrane water wall structure is adopted on both sides of the furnace, which ensures the airtightness of the furnace and improves the boiler thermal efficiency.

3. At the heat receiving surface of the boiler convection tube bundle and economizer, the soot blower interface is reserved. For special fuels (especially those with strong binding properties), necessary measures can be taken to prevent problems before they occur.

4. The inverted "α" type furnace arch technology is adopted, which improves the fuel combustion characteristics and has the characteristics of wide coal adaptability and high combustion efficiency.

5. The furnace arch adopts a water-cooled arch structure, which increases the rigidity and stability of the furnace arch and prolongs the service life of the furnace arch.

6. When the SZL furnace front assembled biomass boiler uses a reciprocating grate, the grate and the fuel have relative motion, suitable for burning biomass loose materials with higher moisture and ash content and lower calorific value.

Boiler products can be designed according to user needs

Key words:

SZL front-mounted biomass boiler assembly

Previous Page:

Next page: