Non-ferrous metals

Release time:

2025-03-03

Author:

Source:

Overview of the Non-ferrous Metals Industry

China is a major producer and consumer of non-ferrous metals and has established a large-scale non-ferrous metals industry. The non-ferrous metals industry is a major energy consumer and pollutant emitter, making it a key focus of environmental protection and governance. With the deepening of industrial transformation and upgrading and supply-side structural reforms, strict environmental protection is an inevitable trend. In recent years, the amount of pollutants emitted per unit of non-ferrous metal product has shown a downward trend, but the output of heavy non-ferrous metals has grown rapidly, and the total amount of pollutant emissions remains large. These pollutants mainly come from boiler emissions. Therefore, outdated production capacity should be resolutely eliminated, and the layout should be accelerated towards regions with abundant environmental capacity, taking the lead in concentrating on regions with energy advantages, especially clean energy and new energy advantages, and concentrating on remote areas that need development. In the development process, energy saving and emission reduction should be achieved to the greatest extent possible, and green development, circular development, and low-carbon development should be vigorously promoted.

Boiler Applications in the Non-ferrous Metals Industry

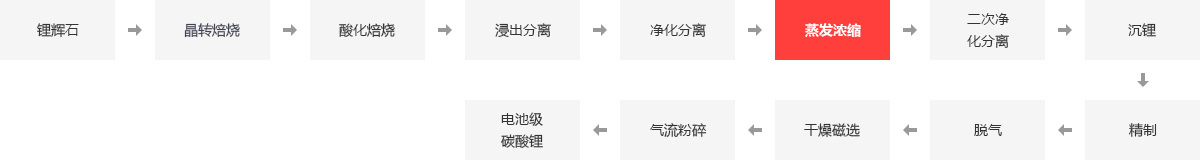

From the perspective of non-ferrous metal applications, China's non-ferrous metals are the foundation of the three major pillar industries of energy, information technology, and materials, and are widely used in infrastructure industries such as transportation, electricity, construction, and communications. Different non-ferrous metals have different smelting and rolling processes. Taking battery-grade lithium carbonate and other light non-ferrous metals as an example, the main processes include roasting, separation, evaporation and concentration, lithium precipitation, refining, drying, and crushing. In the processing of battery-grade lithium carbonate and other light non-ferrous metals, the sulfuric acid countercurrent washing in the water washing process requires the use of direct steam to raise the temperature in the tank to 90℃; the slurry neutralization reaction and product synthesis reaction require the use of coil steam heating to raise the temperature to 90℃ and 95℃; the 95℃ hot water washing used for product washing is also heated using steam coils; product drying is carried out using a steam-heated disc dryer; mother liquor evaporation is carried out by passing steam into the MVR evaporator to evaporate the mother liquor; the 95℃ hot water used for coarse lithium carbonate washing is also heated using coils. These processes all rely on steam boilers to maintain reaction temperature.

Process Flow Chart

Process Flow Chart of the Non-ferrous Metals Industry (Source: Internet)

Previous:

Next:

Application Case

Quick access to technical support and detailed quotes

* Welcome to fill in the following form to improve your product requirements, contact information, equipment use and other information, we will quickly feedback your purchase consultation. You can also contact us through online consultation, e-E-mail and telephone, and our customer service team will further provide you with excellent service.